What is Wire EDM?

Wire EDM Machines conductive materials with electrified wire, delivering ultra-high tolerance, precision parts—efficiently and accurately.

The workpiece is submerged in a dielectric cutting fluid, usually deionized water. As the electrical spark cuts the conductive material, metal content is by removed through melting and vaporization. At the same time, the dielectric cutting fluid cools the material and flushes away particles that have been cut from it — producing burr-free parts that require no secondary machining.

At Northwest Wire EDM, we strive to be your go-to EDM partner by combining expert craftsmanship, cutting-edge technology and unparalleled customer service. From micro hole drilling to complex pattern cuts – when flawless precision matters, remember Northwest Wire EDM!

“When flawless precision matters”

Small Hole EDM

When you need the smallest, most precise holes drilled, think Northwest Wire EDM.

We specialize in fast small hole EDM drilling as small as .010″ in size. Our finished micro-holes are burr-free. We can drill on both soft and hardened metals and offer angled drilling.

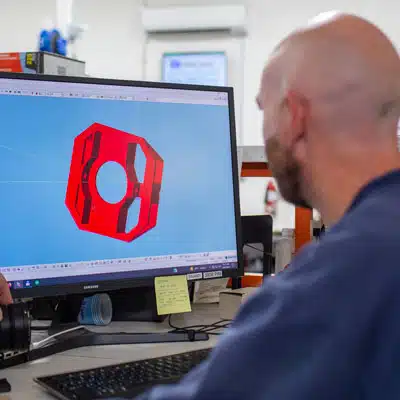

Bring your designs from Prototyping to Production

Rapid Prototyping

Need a Prototype?

We specialize in prototyping, aiding in reviewing and refining designs.

Start RFQ! Learn More

Universities

prototypes • test cuts • short runs

In our University Program, we cut prototypes, perform test cuts, and manufacture short runs for many of the top universities around the country. We enjoy working with and helping both students and faculty with their prototype design plans and short run machining needs.

Expand Your Machining Capabilities

4-axis multi-dimensional Wire EDM machining

Perfect for industries frequently needing tapered cuts.

CNC Machined Parts

NW Wire EDM offers the perfect solution for hardened metal parts requiring precise fits and tolerances. EDM easily cuts narrow slots or close proximity holes.

Precision Blanking & Compound Tooling

EDM machines tooling after heat treatment. Holds extremely tight tolerances allowing taper relief flexibility

Partner With Us

Don't offer wire EDM machining services? Partner with us. Northwest Wire EDM supplements your machine shops' capabilities:

- High-precision prototypes

- Short - Medium volume runs

- Higher volume EDM components

- Advise and expertise

48 Hour Product Turnaround Time

No matter where you are, we can typically get your part cut and shipped out to you within 48-72 hours.

Highest Quality Standards

All parts meticulously cut to meet precise customer expectations

Elite Machinists with Passion, Experience & Process

Our experienced machinists offer over 50 years combined job shop EDM experience!

|

NW Wire EDM provides EDM expertise to tool and die shops, OEMs and contract manufacturers.

Already have your own in-house wire EDM department?

NW Wire EDM will supplement and expand our current capabilities allow you to increase the size of scope of your production runs.

COMMON WIRE EDM APPLICATIONS

Trusted by engineers at:

What clients say

about our cuts

My company has been working with Northwest Wire EDM for almost 30 years. Their professionalism and attention to detail and quality has been stellar. They are easy to work with and very accommodating with our wild emergency requests.

We are a product manufacturer and we rely on Northwest Wire EDM to help us out in those chaotic moments that the industry hands us, they always come through with the quality and assistance required.

We have a great relationship with them and they have never let us down, even with our most complicated geometries. Thank you Northwest for all the help over the last 30 years.

“NW Wire EDM has been my go-to for quality, fast-turnaround part modifications. The team is highly knowledgeable and can identify the most appropriate tolerance given your specific assembly needs. They are professional, nimble, and provide exceptional customer service.”