Industries and Applications

Partner with us • Expand your capabilities • Add Wire EDM Cutting and Small Hole Drilling

Industries and Applications

• Partner with us

• Expand your capabilities

• Add Wire EDM Cutting and Small Hole Drilling

Industries

Northwest Wire EDM serves as an experienced and dependable outsource EDM machining provider. Our expert craftsmanship, understanding of materials and EDM expertise makes us the ideal EDM partner to manufacturers across a broad range of industries.

The parts we manufacture include aerospace, automotive, medical, electronics, and more. From critical components in aerospace assemblies to intricate parts in medical devices, our work contributes to advancing technology and driving innovation in diverse sectors.

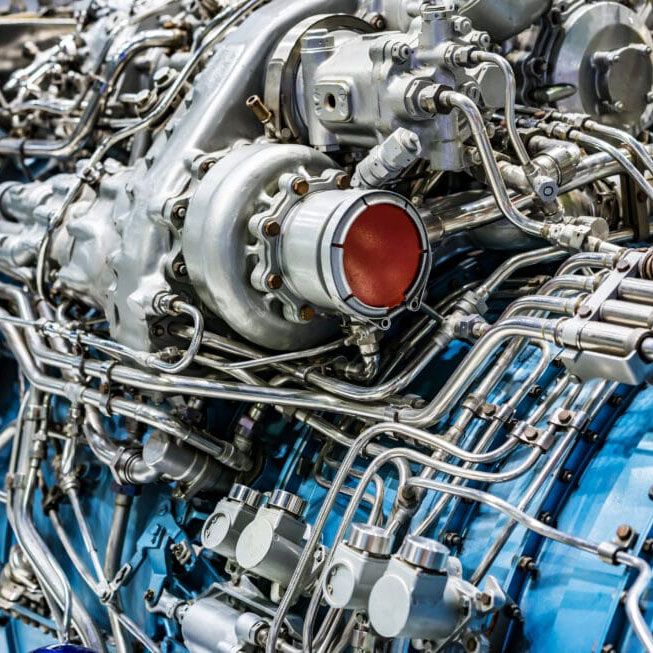

Aerospace & Defense

Northwest Wire EDM provides machining services for aerospace suppliers primarily focusing on development components and spare parts. We are also capable of rapidly replacing defense consumables made from various common & exotic materials.

Automation & Robotics

EDM is ideal for producing low volume complex parts for robotic components and prototypes, such as: end effector tooling, gripper jaws and pinion gears.

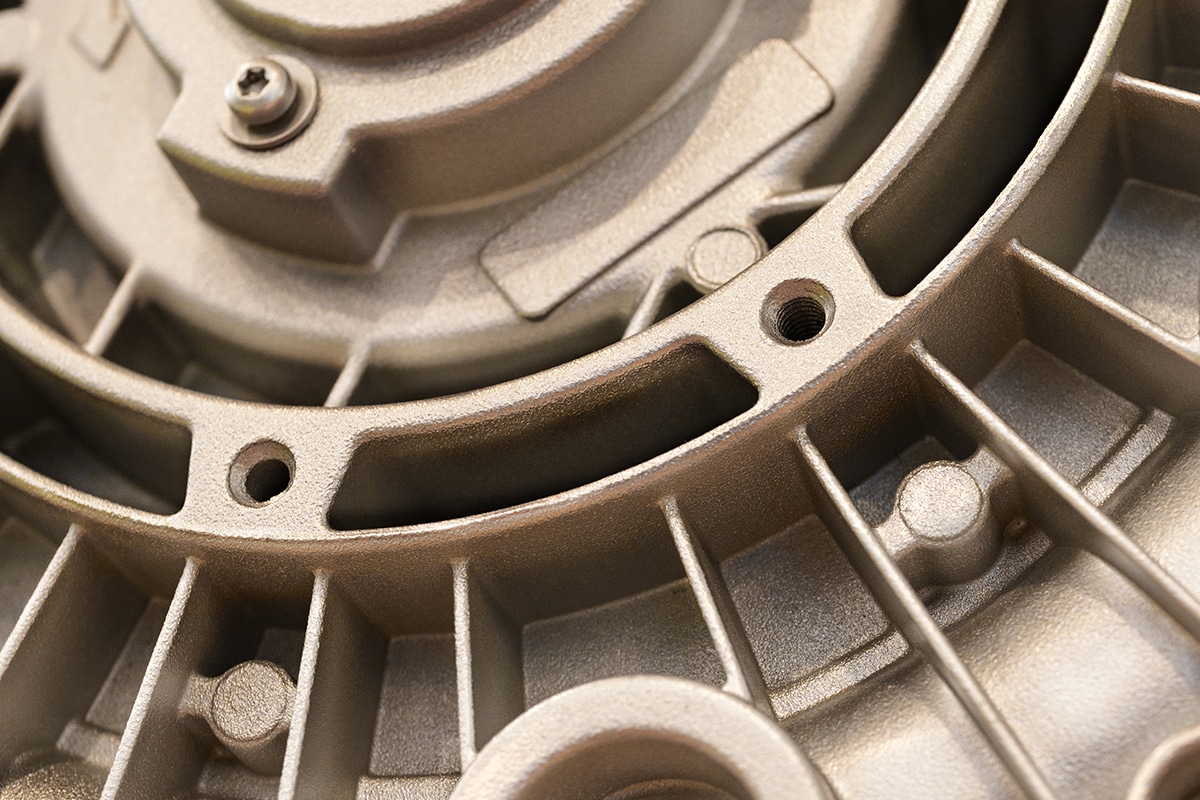

Automotive

We manufacture many precision components utilized in the automotive industry. Examples include: hybrid, EV and electronic system modules, locking system components, and fuel system & production line components.

Cutting Tools

We drill small hole EDM coolant holes in tool bits, end mills, reamers, drills & routers made from high speed steels, carbides, and other hard to machine materials. We also make custom form tools for lathes, four-slide machines, end mills and other manufacturing equipment.

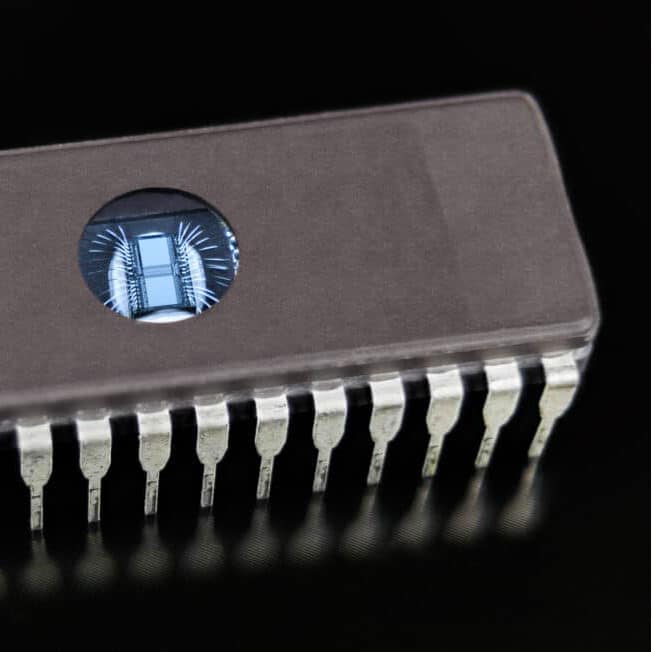

Electronics

Precision machining on intricate components made from exotic materials, like tungsten, hastelloy, inconel, waspalloy, and polycrystalline diamond.

Energy / Renewable Energy

Durability & dependability are paramount for the intricate components used in the energy industry. We have produced solar energy cell components, power transmission components and deep cell battery tooling & molds.

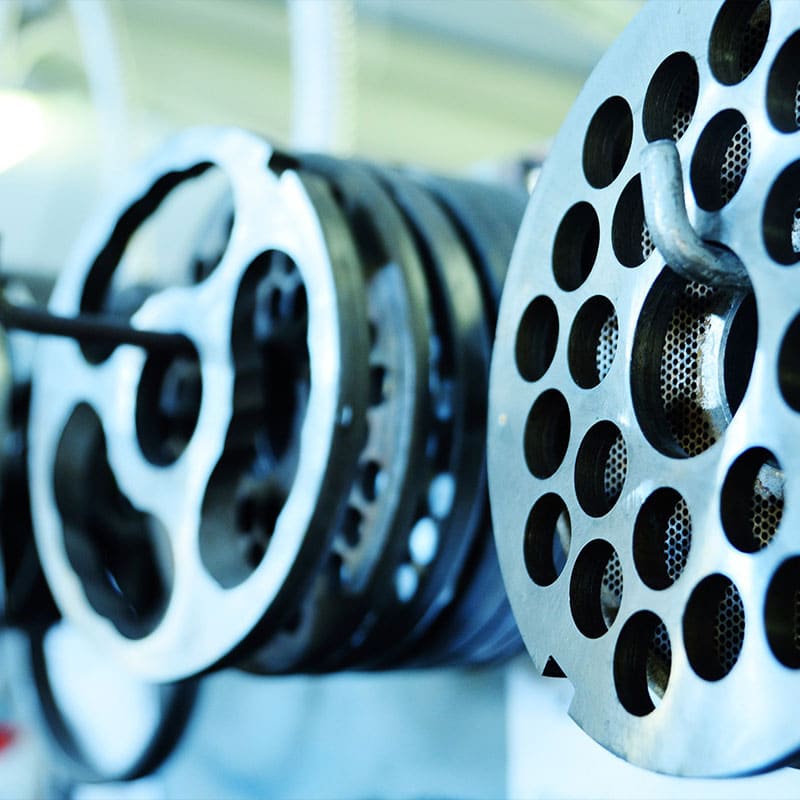

Food Processing

We manufacture custom parts, repair parts, and consumable components used for food cutting, packing, stamping and nozzle parts.

Medical / Orthopedics

We produce medical components, such as: bone plates, resection cut blocks, endoscopic components, and laparoscopic graspers & forceps. We work with many materials like titanium, platinum, medical grade stainless steel, tungsten and nitinol.

Optics & Photonics

We make many intricate parts requiring fine finishes & tolerances, including: fiber optic connectors, nano-positioning parts, heat sinks, optic collimators and laser diode sub-mounts & arrays.

Packaging

We specialize in packaging die components with tight tolerances (i.e., zero-clearance) including paper & cardboard, plastic and vacuum packaging.

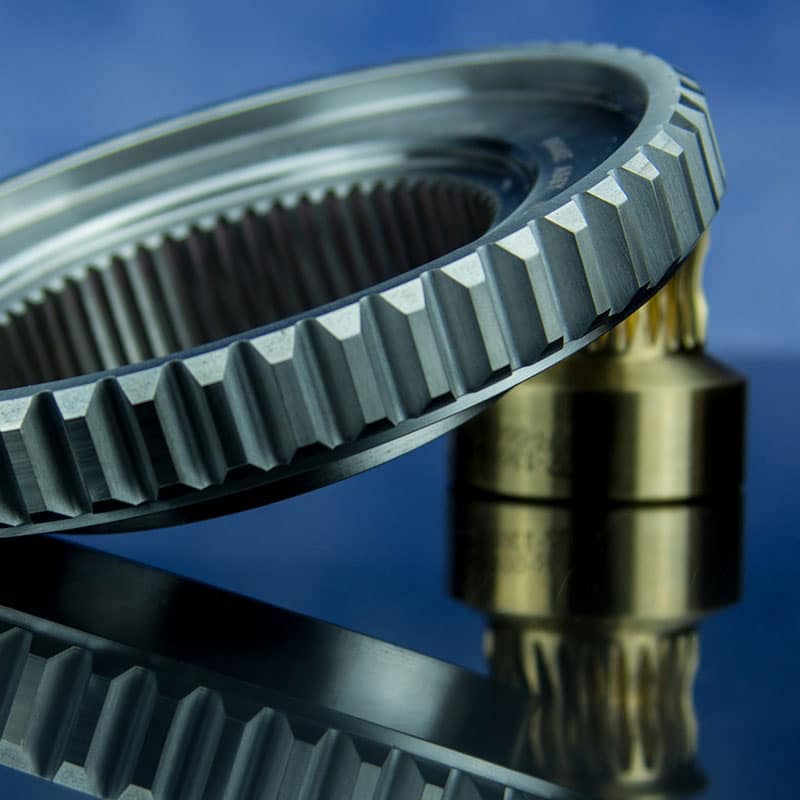

Power Generation & Turbines

Wire EDM is ideal for cutting exotic materials that produce ready-to-use parts that are virtually burr-free. We’ve created power generation components from various metals, including: stainless steel, nickel-based super alloys, hastelloy, inconel, invar and kovar.

Recreation / Sporting Goods Manufacturing

Precision machining for mold & die components used for manufacturing gages, custom sporting equipment, forging tooling and other applications.

Applications

Northwest Wire EDM stands out as a highly capable and reliable provider of EDM machining services. We specialize in augmenting our customers’ machining capabilities and manufacturing parts that play integral roles across a broad range of applications.

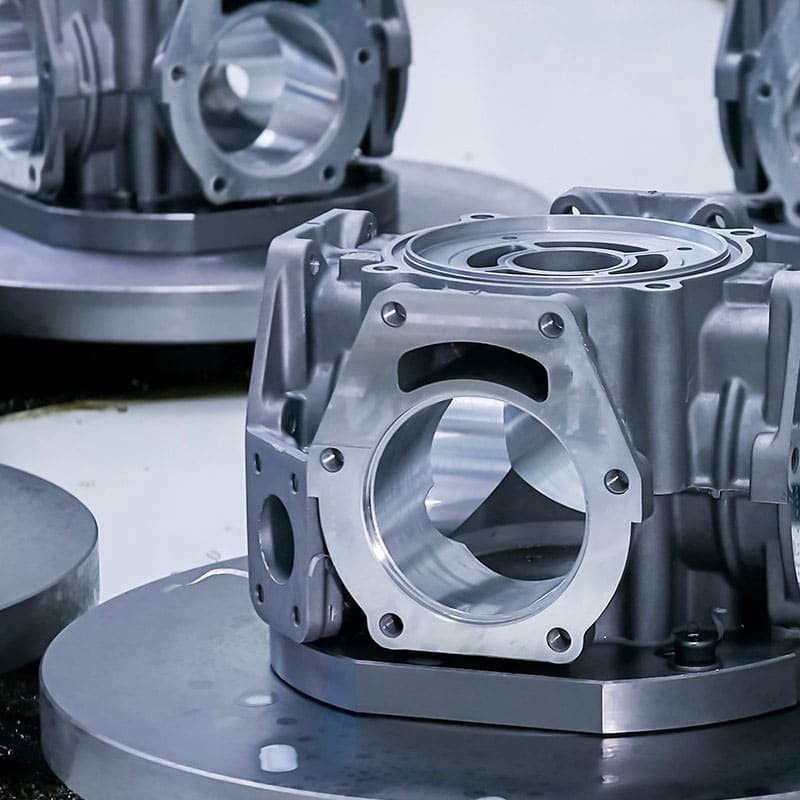

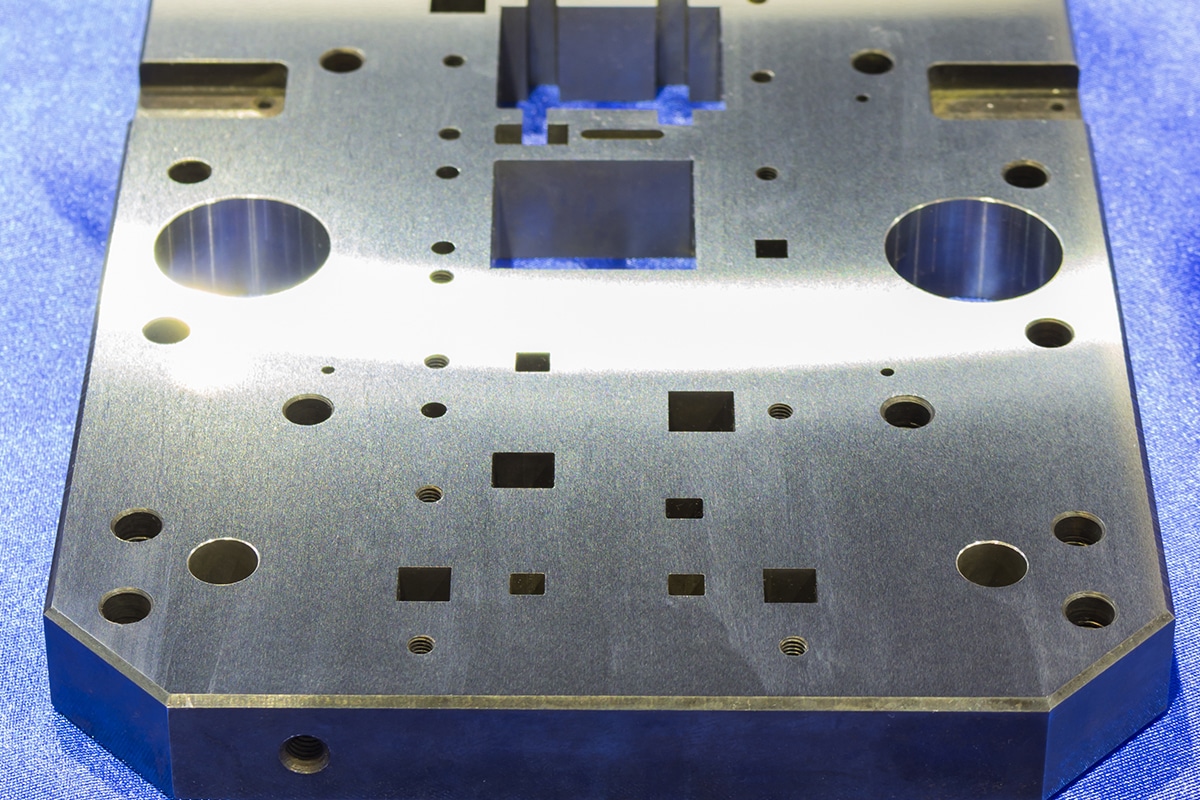

CNC Machined Parts & Contract Manufacturing

Our Wire EDM services are used in CNC parts made from difficult to machine materials requiring precise fits & tolerances, narrow slots such as collets and small close proximity holes.

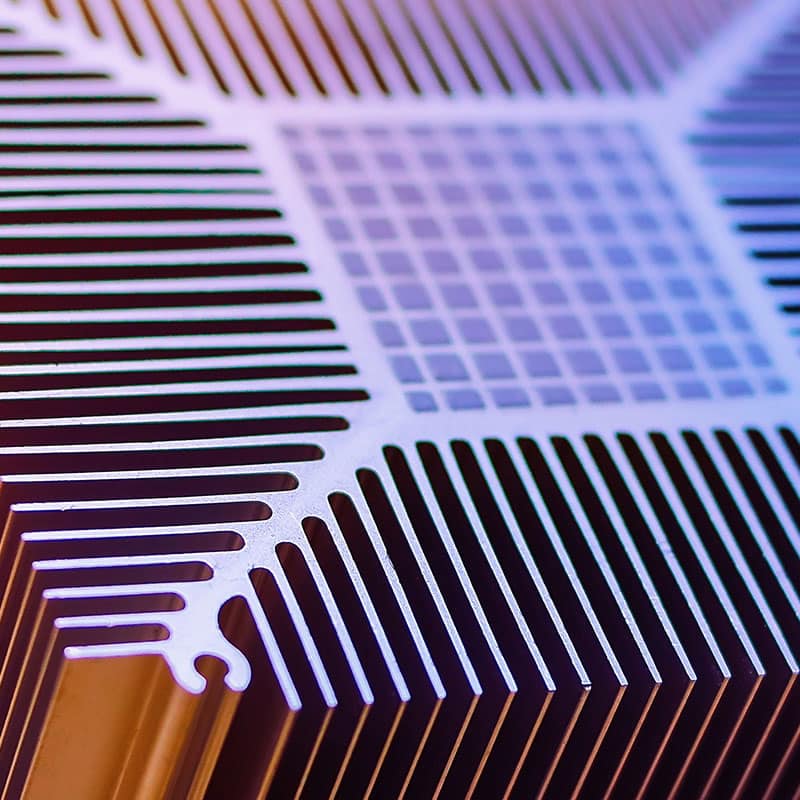

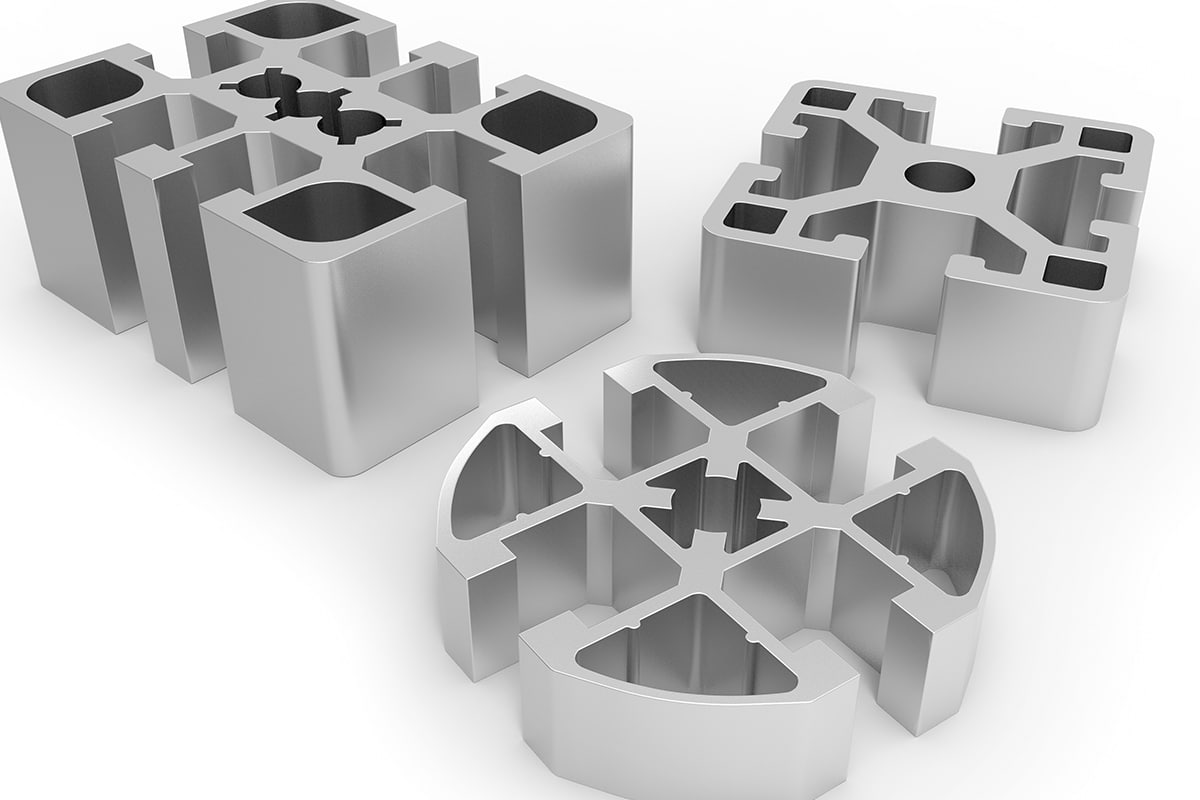

Extrusion Dies &

Sizing Plates

4-axis Wire EDM can be used to machine metal and plastic extrusion dies where geometries consisting of two different shapes on parallel planes are connected by a ruled surface. Any industry needing a tapered cut can benefit from this multi-dimensional (U-V) cutting.

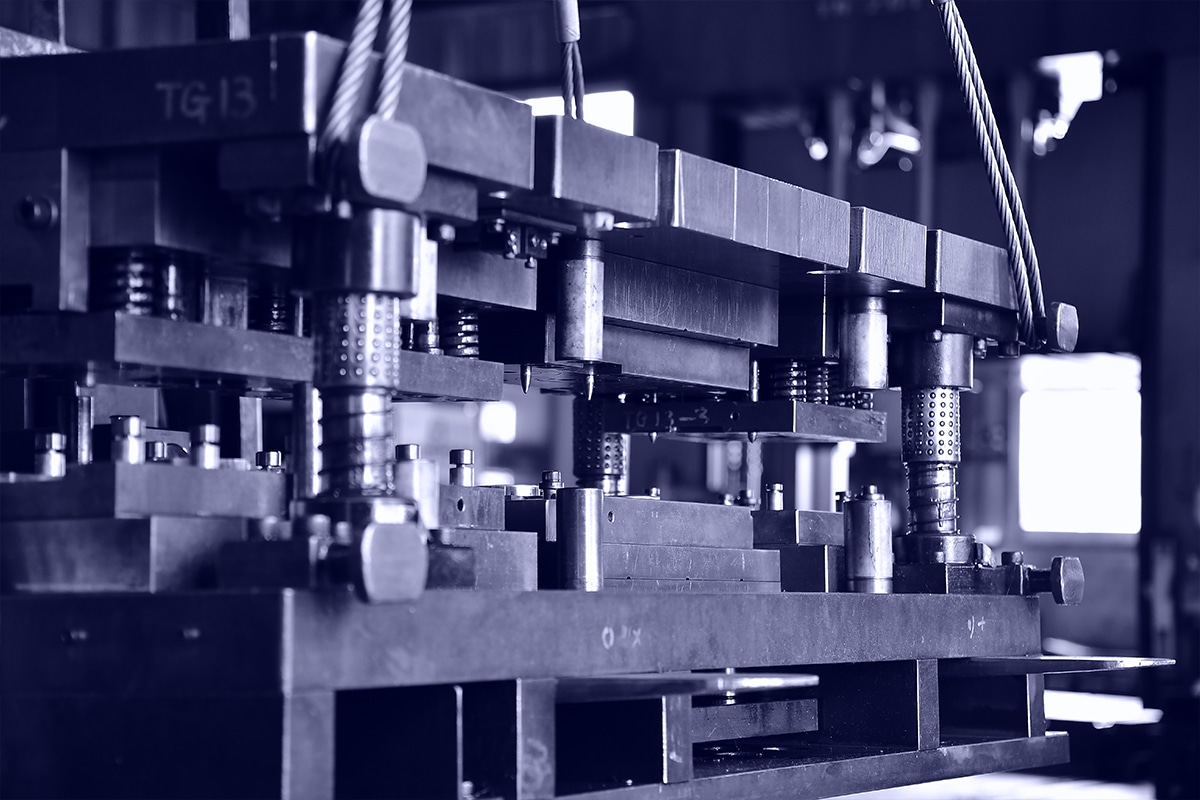

Fine Blanking & Compound Tooling

Wire EDM can machine tooling after heat treatment so extremely tight tolerances can be held. EDM allows for the flexibility to apply taper relief as required.

Firearm Components / Gun Parts

We specialize in machining parts requiring repeatable precision or detailed geometries, including hammers, lower receivers, triggers and true-glow sights.

Matched Metal

Tooling

Wire EDM produces ultra precision cutting clearances between the punch and die resulting in excellent edge quality on final trimmed parts.

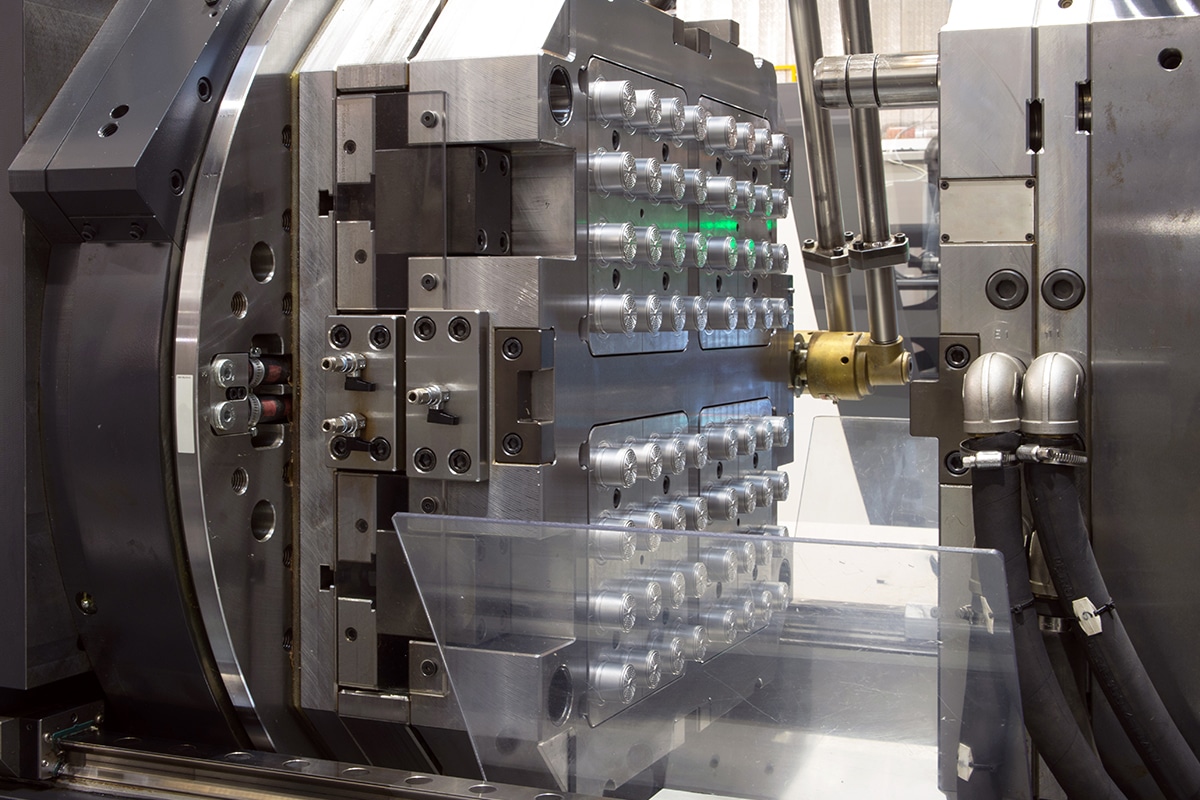

Plastic / Metal Injection Molding Components

Wire EDM can be used to produce many critical molding components, such as mold slides, core pins, retainers and core & cavity parting lines.

Powdered Metal Parts & Tooling

Wire EDM is ideal for manufacturing sizing tools, as well as tooling for prototype powdered metal parts requiring enhanced surface finishes and tolerances.

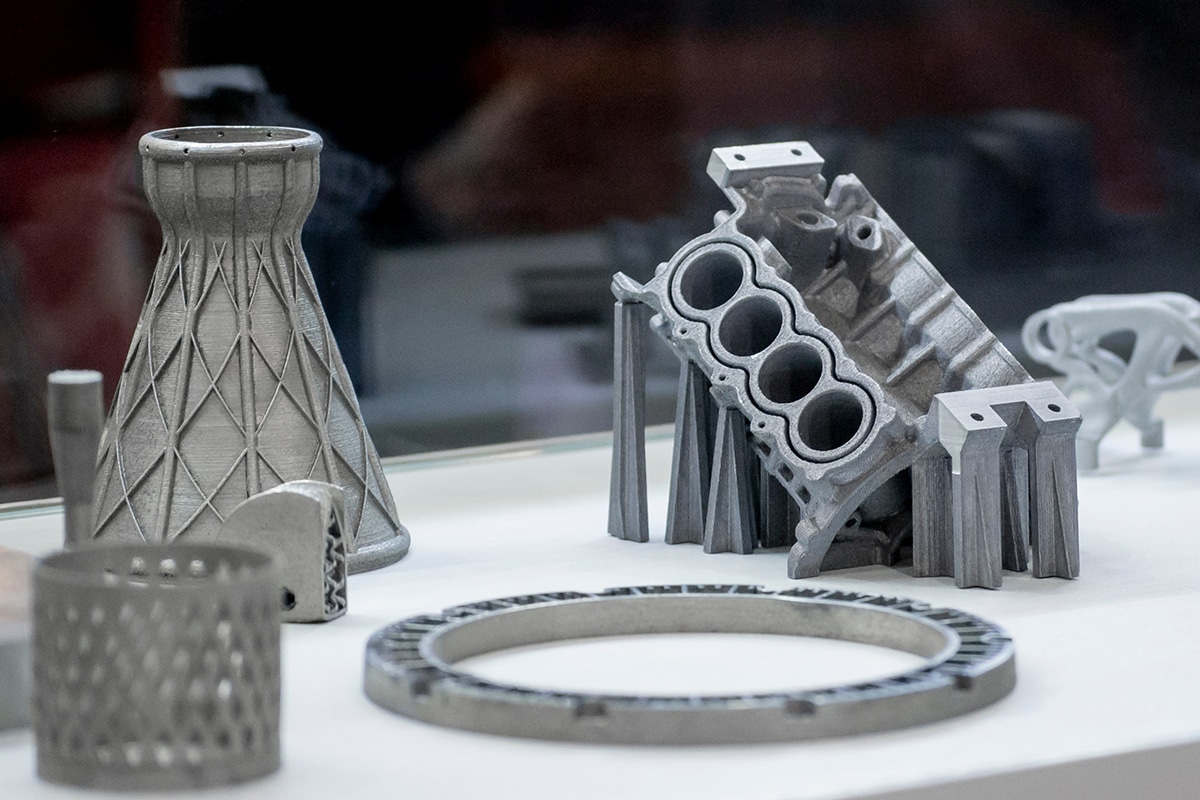

3D Printed Parts

Wire EDM is used to remove parts from the build plates & separate stacked parts, as well as refining surface finish & tolerances of critical part features.