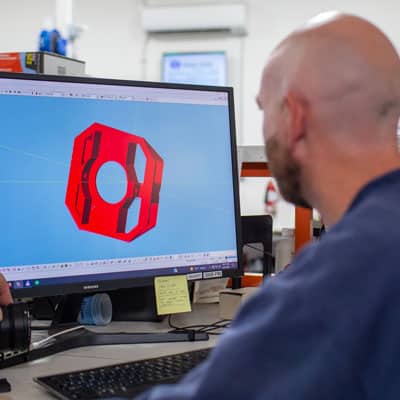

Rapid Prototyping

Bring your designs from Prototype to Production

Seamless Transition for Success

Bridge the Gap Between Prototype and Production

Prototyping is a crucial stage of part development; allowing your designers to test and refine their designs before moving to full-scale production. Northwest Wire EDM is here to support your prototyping needs.

Rapid Prototyping Services

Northwest Wire offers rapid prototyping services to bring your designs to life quickly and efficiently. Our expertise in advanced Wire EDM technology facilitates precise and intricate prototyping, ensuring your designs are accurately replicated in the initial stages of part development.

Design Optimization

Northwest Wire EDM machinists work closely with your team to optimize your prototype designs, taking into consideration such factors as material selection, geometric complexity, and manufacturing feasibility. Our collaborative approach ensures your prototypes’ not only showcase your concept, but also lays the groundwork for larger scale production.

Material Versatility

Northwest Wired EDM’s machining experience covers a wide range of materials – from common metals like aluminum to hardened materials like carbides or super alloys like inconel or beryllium copper. Whether your prototype is for space, aerospace, medical devices or industrial parts, Northwest Wire offers the expertise to work with diverse materials to meet your specifications.

Precision and Quality Assurance

Northwest Wire EDM is committed to delivering prototypes of the highest quality and precision. Our stringent quality control measures adhere to ISO 9001 guidelines, ensuring your prototype meets strict tolerances and performance standards.

Iterative Prototyping

Northwest Wire EDM understands prototyping often involves frequent iterations and refinements to achieve your desired final part. Our flexible manufacturing approach allows for iterative prototyping, making adjustments based on your feedback refinements and testing results.

Expert Guidance and Support

The Northwest Wired EDM team of experienced professional machinists will provide your team expert guidance and support throughout your prototypes’ development. Whether you have questions about design optimization, material selection, or production feasibility, Northwest Wire EDM is here to your team make the most informed decisions.

Click here if you’re ready to start the process.

Short Production Runs

Northwest Wire EDM specializes in handling short production runs with efficiency and precision.

Optimized Workflow

Northwest Wire EDM designs optimized workflows specifically tailored for short production runs. Your parts will be manufactured efficiently without compromising quality, precision, or accuracy. Wire EDM technology is well-suited for short runs where precision and consistency are crucial.

Collaborative Contract Manufacturing

Timely Delivery

Northwest Wire EDM understands the importance of meeting deadlines for short production runs. Our team is committed to timely delivery of your parts. Parts will be delivered according to your schedule.

Flexibility and Scalability

Although Northwest Wire EDM specializes in rapid prototyping and short run contract manufacturing, our team also offers the flexibility and scalability to accommodate medium run production too. You can trust our wire EDM equipment will manufacture your part around the clock until the run is complete. Whether you need to adjust quantities, make design modifications, or scale up production, Northwest Wire EDM can adapt to suit your requirements.

"Emergency" 48 Hour Turnarounds

Have an “Emergency, All Hands on Deck” situation? Trust Northwest Wire EDM to come to the rescue! Upload your drawings right away. We’ll get back to you quickly with an estimate and delivery schedule!